Table of Contents

ToggleThe global solar market may exceed 2100 GW by 2030.

The average growth rate of Photovoltaics has been about 33% per year over the past ten years.

This colossal growth of the solar sector has inspired scientists to push themselves to make further advancements in solar panels that can perform better and suit other residential consumers’ needs.

Out of various advancements, one such noteworthy development is the PERC (Passivated Emitter and Rear Cell) technology. PERC solar panels provide excellent benefits from an energy generation point-of-view which was absent in the previous models.

This article will act as a comprehensive guide on PERC panels which may help you understand its utility and functioning up to a possible extent.

What are PERC solar panels?

The development of PERC technology started in the 1980s. Yet, the idea was not commercially significant back then because the results achieved in research and mass-produced units had a big gap. But over time, scientists have perfected the set-up and made the PERC model commercially acceptable.

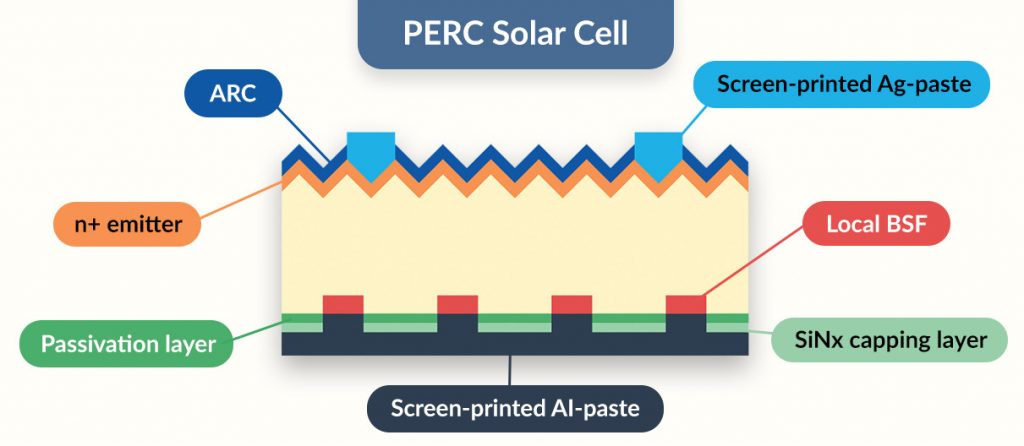

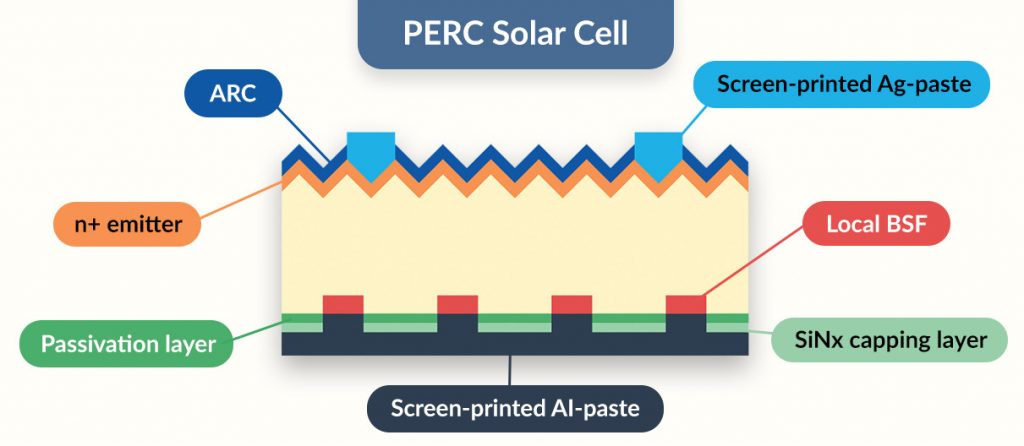

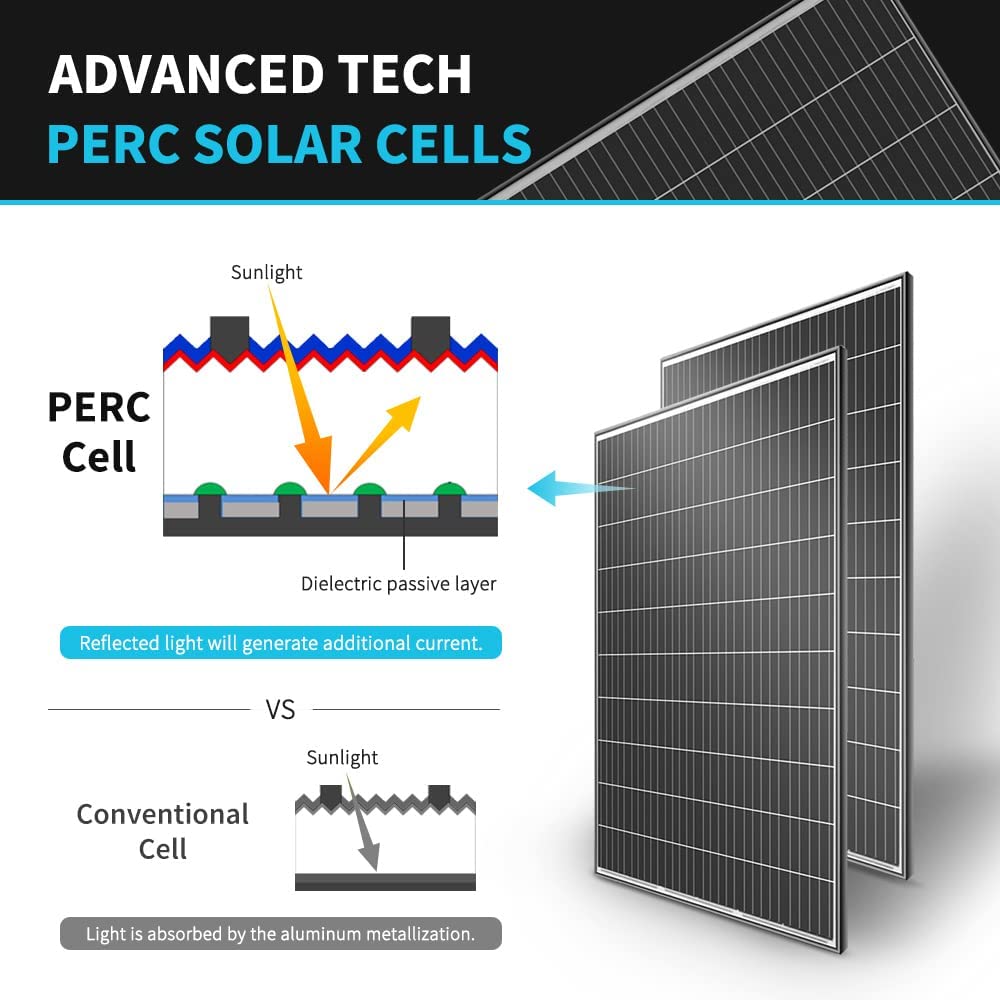

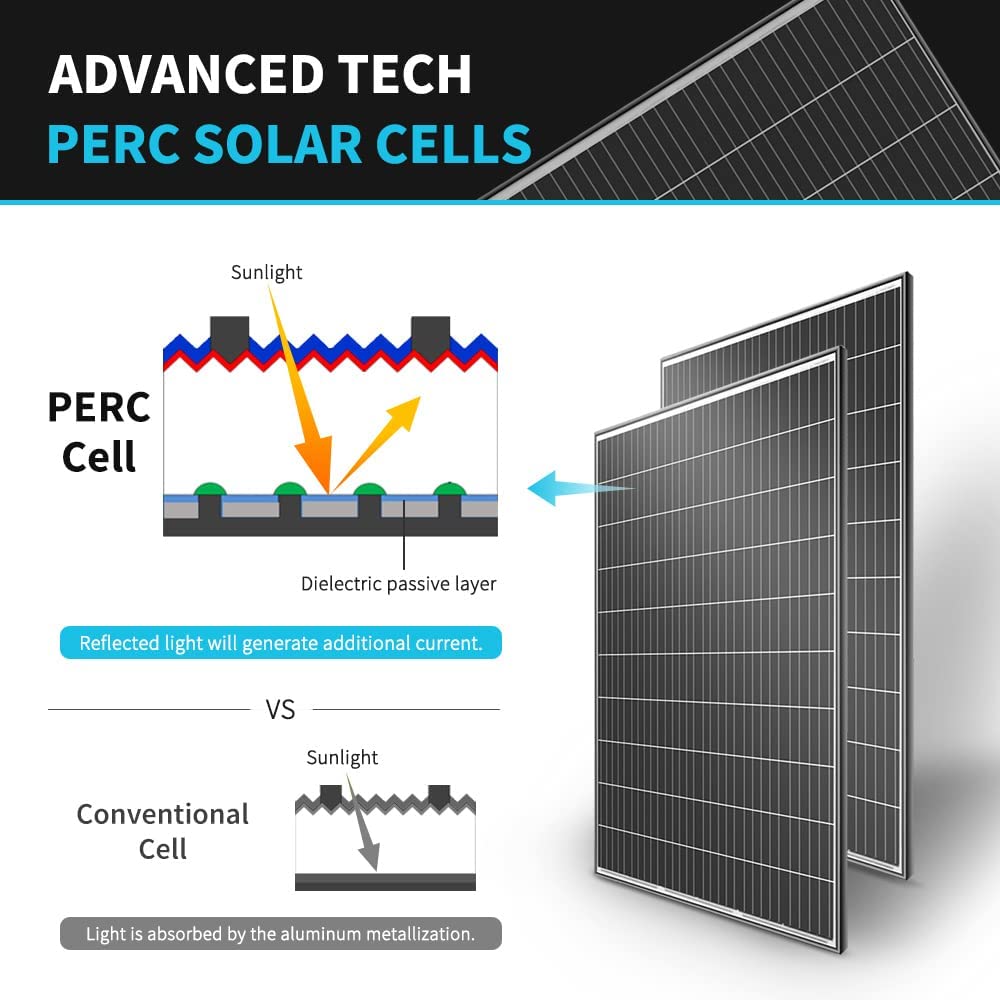

PERC cells have an additional layer on the rear side of the solar cells which is absent in the traditional ones. This layer enhances internal reflectivity and eventually elevates the electricity generation capabilities of the solar panel.

PERC solar cell manufacturing process

The overall construction of a PERC solar cell is not very different from a normal solar cell.

The PERC cells require only two additional steps over a traditional panel for its manufacturing :

- Preparation of dielectric passivation layer.

- Chemical or laser engraving for opening pockets in the rear passivation layer.

The structure of a PERC solar cell from front to rear is as follows :

- Screen-printed Silver paste front contact

- Anti-Reflective Coating (ARC)

- Silicon wafers for forming the P-N junction

- Local Aluminum Back Surface Field (Al-BSF)

- Dielectric passivation layer

- SiNx Capping Layer

- Screen-printed Aluminum paste layer

Types of PERC solar cells

PERC solar cells can be divided into two types, Mono PERC solar cells and Poly PERC solar cells.

Mono PERC solar cells

The mono PERC solar panels are an advanced, upgraded form of conventional monocrystalline solar panels which use homogenous silicon for cell preparation.

Mono PERC cells use a dielectric passive film placed on the solar cells’ rear side. This layer helps redirect the unabsorbed sunlight back towards the solar cell. Hence, it increases the overall efficiency of the PERC panel by a significant margin.

Poly PERC solar cells

Poly PERC solar cells, also called polycrystalline PERC cells, are made of an amalgam of silicon shards. The poly cells being a heterogeneous product, are less efficient than mono PERC cells, but it is undoubtedly the cheaper option.

Like the former, the poly cells have a rear dielectric layer to improve their performance. But in comparison to mono PERC cells, the output of poly cells is on the lower side.

You can go for poly PERC cells if you want to go solar and expect good performance without making a hole in the pocket.

PERC solar panel efficiency

PERC panels are over 1% more efficient than traditional silicon panels, which eventually helps in generating 5% more energy than a typical solar setup.

Due to their increased efficiency, the PERC solar panels are expected to be more dominant than traditional panels in the coming years.

Let us explore the reasons why PERC technology is more efficient.

Reflects light back through the solar cell

Sometimes the photons are not correctly caught by the solar cells. This phenomenon occurs when the sun rays are of greater wavelength (above 1180nm). In this case, they don’t fall in the absorbable palette of the cell.

The additional dielectric passivation layer placed on the panel’s rear side helps reflect back light, which gets missed by the photovoltaic cell through the help of total internal reflection.

This property of the PERC cells helps increase the solar panel’s overall efficiency.

Reduces recombination of electrons

When the electrons move inside the p-n junction during the energy generation process, a phenomenon called “electron recombination” occurs.

In simple words, the electrons recombine with the surface of the silicon cells due to the presence of “dangling bonds” in the crystalline structure of silicon.

This creates a blockage for the free electrons, disrupting the movement in the solar cells. As a result, the energy efficiency of the solar panel is diminished.

In PERC cells, the passivated layer helps in reducing the recombination of electrons using the additional Sio2 and Al2O3 present in the dielectric layer by tightening up the “dangling bonds” of the silicon lattice.

Reduces absorption of heat

Solar panels are built in a way that they can absorb only a range of wavelengths. For example, a conventional solar cell can absorb sunlight in wavelengths up to 1180 nanometers.

If sun rays fall on a solar panel with a wavelength higher than 1180nm, the sunlight is absorbed by the opaque black sheet behind the silicon solar cells. This increases the overall temperature of the solar panel.

As a result, solar panels perform at a lesser efficiency rate when the system is in a thermally lifted condition.

PERC cells are engineered specially to reflect wavelengths of 1180nm or above to the silicon cells so they can be absorbed. This feature not only helps the solar panels to maintain thermal equilibrium, it also adds up to the efficiency of the solar panels.

PERC solar panels pros and cons

PERC solar panels’ advantages

- Enhanced energy efficiency: PERC solar models are almost 1% more efficient than traditional silicon solar panels. The figure may appear tiny, but when you calculate the cost per unit of energy upon investment for a full PV system, it will be around 5% overall.

- Requires less area: Since PERC solar panels are more efficient than the traditional ones, it means you’ll need fewer number to create the same power as compared to a regular panel. Hence, using these would be a fantastic choice if you have a small area or roof space for installation.

- Less labour cost and reduced BOS: As fewer PERC panels can generate the same electricity, it eventually means you’ll have to pay less labour costs for installation, inverters, wiring and other Balance of Systems (BOS).

- Functional in undesirable places: In general solar panels can’t absorb higher wavelengths and their efficiency also decreases in areas where the temperature is high.

PERC panels can function in extreme environments. Due to the benefits of lower heat absorption, they can stand out in hot locations. In addition, they can work in low light conditions for their increased light absorption capability.

PERC solar panels’ disadvantages

Higher Cost: We know that fewer PERC panels are required to produce an equivalent amount of energy. Still, it is relatively costlier than regular silicon panels.

The price factor can influence a solar enthusiast to choose a simple monocrystalline or polycrystalline panel instead of PERC solar panels.

Solar manufacturers are shifting towards PERC readily. Therefore, with the increase in demand and production, the cost of PERC panels will go down in the near future.

Light-Induced Degradation (LID) – LID, also known as UVID (UV light-induced degradation), is a chemical process that occurs in the PERC cells, which reduces the system’s efficiency.

When sunlight falls on the PERC cells for the first time, the heat causes the free 02 radicals of the silicon lattice to form boron dioxide. This chemical reaction is the main reason for the occurrence of LID.

Potential – Induced Degradation (PID) – Like LID, PID is also a discursive process. It occurs in a PERC cell when a stray current is created between the solar cells and the encapsulation. This event occurs due to the narrow gap between the cells and the capsule frame.

Over the years, continuous usage can also polarize the Al2O3 layer of the PERC cells from the accumulation of positively charged Al2O3 ions on the rear side of the passivation layer to induce PID.

Recently PERC manufacturers are trying to overcome the effects of LID and PID by using better designs and advanced engineering. Therefore, we can hope that, with time, scientists will eliminate or completely minimize the effects of LID and PID in PERC solar panels.

Also read our article on “Solar panel maintenance.”

Perc solar cell manufacturers

There are a lot of key players in the solar industry who manufacture PERC solar cells. Some of the prominent ones are –

- Renogy Solor

- Adani Solar

- Canadian Solar

- Sunpro Power

- 3D Energy

- First Solar Inc.

- CETC Solar

- Aleo Solar

PERC solar panels price

The price of PERC solar panels can vary according to brands, energy generation capacity and build quality. For your easy understanding, we are making a hand-curated list that will hopefully give you a brief idea of PERC solar panels’ prices.

- Waaree 540W 144 Cells Monocrystalline PERC Solar Panel, WSMD-540 – USD297

- Jackery SolarSaga 100X Portable Solar Panel – USD299.99

- Adani 370W/30V Monocrystalline Perc Solar Panel – 223 USD

- ZunSolar Carat 24 ZR 180W Mono PERC Solar PV Module Panel – 89 USD

- ZunSolar Carat 24 ZR 100W 12V Mono PERC Solar Panel – 55 USD

- Loom Solar 440W 24V 144 Cells Mono PERC Shark Solar Panel, LS440W (Pack of 2) – 505 USD

With the numerous benefits a PERC solar panel brings, it easily places itself above regular solar panels.

These energy-dense panels can help you generate the same energy as a regular panel with fewer panels.

You also don’t need to worry about your locality, temperature and geographical location. PERC cells can tackle extreme temperatures and also function in low light conditions.

Lastly, when you use fewer panels, the cost of labor, wiring, inverters and other Balance of Systems (BOS) goes down automatically.

Overall, PERC solar panels can be a promising and budget-friendly solution for solar enthusiasts looking to maximize energy production within a limited area.